Continuous Filament Super Winding Process

In order to keep the quality of GRP Pipes within the requirements of related international A.S.T.M and AWWA standards it is necessary to control perfectly all the process parameters. The latest technology and control system available in the market for GRP Pipe manufacturing is the continuous filament super winding process developed and used by AKBOR. The Level-1 hardware consists of High Performance PLC and Operator HMI. The PDI data like diameter, stiffness and pressure class are entered manually by the Operator.

The manufacturing of GRP pipe is carried out through a mandrel formed by winding a continuous steel band over a horizontal beam provided with supporting disks sized according to the diameter of the pipe required. The steel band moves in the axial way sliding over the ball bearings inserted in beam grooves. At the end of the mandrel, the steel band is guided by exit head into the mandrel inner tube, which supports the exit head. On the opposite end of the mandrel near the cam, the steel band is wound on the mandrel again. In this way the steel band forms a smooth surface mandrel with simultaneous advancing in the axial direction

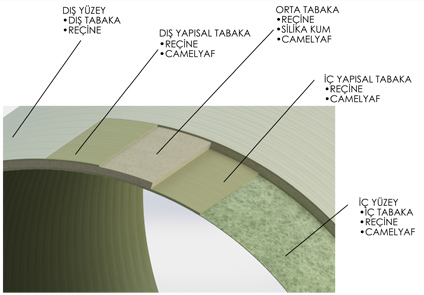

The glass fiber laminate is applied onto the moving mandrel according to the following procedure.

Firstly a polyester film is wound on the mandrel, followed by a surfacing mat, both of them supported by proper winders. Glass roving together with chopped glass, sand aggregate, polyester resin is applied simultaneously on the proper mandrel positions according to GRP Pipe design specifications. At the end, a layer of surfacing mat is applied.

|

|

According to the process philosophy, the layer applied next to the steel tape provides the required chemical resistance (inner layer), while the material supplied over the liner layer represents the mechanical resistant outer layer.

Following curing phase the GRP pipe is cut to the preset length and conveyed by run out table to calibration/chamfering, hydro test and coupling stations.

Technical Properties of AKBOR GRP Pipes

AKBOR GRP Pipes and Fittings are manufactured by using Continuous filament super winding process. Main advantages and technical properties of GRP Pipes compared to other type of pipes are given below;

Resistant against corrosion and chemicals and don’t need to be painted

Very good hydraulic and mechanical properties

With the 2 way EPDM gasket provides 0 leak-tightness.

Due to its low weight easy and fast installation.

Very low maintenance cost

Can be manufactured conform to design at requested lengths between 0,3-15m

It is healthy and meets all the requirement of ISO 14001

Life expectancy is more than 50 years.

Do not require expensive interior and exterior coating and cathodic protection.

There is not any current induction due to ground current (Coming from lightning or other surrounding electrical network).

AKBOR GRP Pipes Hydraulic Properties

The large inside diameter and the quality of the inside surface of AKBOR pipes give the pipe system the ability to transport and convey a greater volume of fluid, as compared to a steel pipe with the same diameter. The maximum flow permissible in AKBOR pipe is 7.5 meters/second.

The Manning number in AKBOR pipes is equivalent to 0.009. The Hysen-Williams coefficient is C=150. The head loss curve according to the pipe diameter and flow volume is based on the Darcy-Weisbach and Mody equations (for a Reynolds number higher than 4000)

The movement of the liquid head has energy that depends on the weight of the liquid and its speed. A sudden stop of the flow (by closing a valve) transforms this energy into a high-pressure force, or water hammer. The longer the pipe and higher the flow speed, the greater will be the water hammer. In AKBOR pipes the water hammer that is produced is only a third of the water hammer produced in steel pipes.

Product Range and Application

The product ranges of AKBOR GRP Pipes are given below;

| Lengths: | 0,3m to 15m | |

| Diameter Range (DN): | 300mm - 4200mm | |

| Pressure Class ES (PN): | 1 – 32bar | |

| Stiffness Classes (SN): | 2.500 N/m2 – 5.000 N/m2 – 10.000 N/m2 |

GRP Pipes are widely used in the following applications;

• Main pipes and branch lines for potable water distribution systems.

• Pipes for sewage systems. Main and subsidiary sewage

• Collectors by pressure and gravity flow.

• Pipes for waste water systems.

• Pipes for cooling systems of power stations (sea water).

• Pipes for submarine systems.

• Pipes for systems in chemical plants.